Spent dialysate, a byproduct of hemodialysis, is traditionally discarded but holds significant potential for resource recovery within a circular economy framework. This literature review synthesizes research on the composition, ecotoxicological risks, treatment technologies, and resource recovery opportunities of spent dialysate. Characterized by high salinity, nitrogenous compounds, and contaminants like antibiotic resistance genes (ARGs), per- and polyfluoroalkyl substances (PFAS), and microplastics, spent dialysate poses moderate environmental risks, including eutrophication and antimicrobial resistance dissemination. Advanced treatment methods, such as reverse osmosis (RO) and nanofiltration (NF), effectively remove contaminants, while struvite crystallization and energy recovery via heat exchangers and microbial fuel cells (MFCs) enable the valorization of water, nutrients, and energy. These approaches reduce carbon emissions by 30–50% and offer economic benefits through cost savings and revenue generation. However, regulatory gaps, high infrastructure costs, and limited research on microplastics highlight the need for further investigation to fully realize the circular potential of spent dialysate. This review synthesizes these challenges, identifies key implementation barriers, and outlines critical research priorities to translate this promising concept into sustainable practice.

Dializado gastado, un subproducto de la hemodiálisis, tradicionalmente se descarta, pero tiene un gran potencial para la recuperación de recursos dentro de un marco de economía circular. Esta revisión bibliográfica sintetiza investigaciones sobre la composición, los riesgos ecotoxicológicos, las tecnologías de tratamiento y las oportunidades de recuperación de recursos del dializado gastado. Caracterizado por su alta salinidad, compuestos nitrogenados y contaminantes como genes de resistencia a antibióticos (ARG), sustancias perfluoroalquiladas y polifluoroalquiladas (PFAS) y microplásticos, el dializado gastado representa riesgos ambientales moderados, como eutrofización y diseminación de resistencia antimicrobiana. Métodos avanzados de tratamiento, como la ósmosis inversa (RO) y la nanofiltración, eliminan eficazmente los contaminantes, mientras que la cristalización de estruvita y la recuperación de energía mediante intercambiadores de calor y celdas de combustible microbianas (MFC) permiten valorizar agua, nutrientes y energía. Estos enfoques reducen las emisiones de carbono entre un 30-50%, y ofrecen beneficios económicos mediante ahorros de costos y generación de ingresos. Sin embargo, las brechas regulatorias, los altos costos de infraestructura y la investigación limitada sobre microplásticos resaltan la necesidad de más estudios para aprovechar plenamente el potencial circular del dializado gastado. Esta revisión sintetiza estos desafíos, identifica las barreras clave para la implementación y esboza prioridades de investigación críticas para trasladar este concepto prometedor a la práctica sostenible.

Hemodialysis, a critical treatment for end-stage renal disease, generates substantial volumes of spent dialysate, a wastewater stream traditionally managed as a disposal challenge. Recent research has shifted focus toward its potential as a resource within a circular economy framework, emphasizing water, nutrient, and energy recovery to enhance sustainability in healthcare.1 Spent dialysate's distinct properties make it a promising candidate for valorization,1,2 but contaminants like antibiotic resistance genes (ARGs),3 per- and polyfluoroalkyl substances (PFAS),4 and microplastics5 raise environmental concerns. This review synthesizes the literature on spent dialysate's characteristics, ecotoxicological risks, possible treatment technologies, and resource recovery potential, highlighting opportunities and challenges for sustainable hemodialysis practices.

Review methodologyA systematic review of the literature was conducted to synthesize current knowledge on the resource recovery potential of spent dialysate from hemodialysis. The primary objective was to identify and evaluate technological strategies for its valorization within a circular economy framework, and to assess their environmental and economic impacts.

The search was executed across three major scholarly databases: Scopus, PubMed, and Web of Science. The investigation targeted English-language articles published between January 2000 and June 2024 to capture the evolution of relevant technologies and policies. The search strategy utilized a combination of keywords and Boolean operators to maximize coverage: (“spent dialysate” OR “dialysis wastewater” OR “hemodialysis effluent”) AND (“circular economy” OR “resource recovery” OR “valorization” OR “water reclamation” OR “nutrient recovery” OR “energy recovery”).

Following duplicate removal, 46 unique articles were retained for screening. The titles and abstracts of these articles were screened for relevance based on predefined criteria. Studies were included if they focused on the composition, management, treatment, environmental impact, or resource recovery pathways of spent dialysate. Articles that focused exclusively on clinical dialysis techniques without addressing effluent management were excluded.

The full text of the remaining relevant articles was assessed for eligibility. To ensure a comprehensive analysis, the reference lists of these key publications were hand-searched for additional pertinent sources, a process known as snowballing. This rigorous selection process resulted in the final inclusion of 15 references that form the core evidence base for this review.

The quantitative data presented in this manuscript, including figures on energy consumption, cost estimates, and potential savings, are derived from the data reported in this compiled literature. Where specific calculations are presented, for example struvite production or CO2 savings, they are based on applying these literature-derived figures to standardized scenarios, as noted in the text.

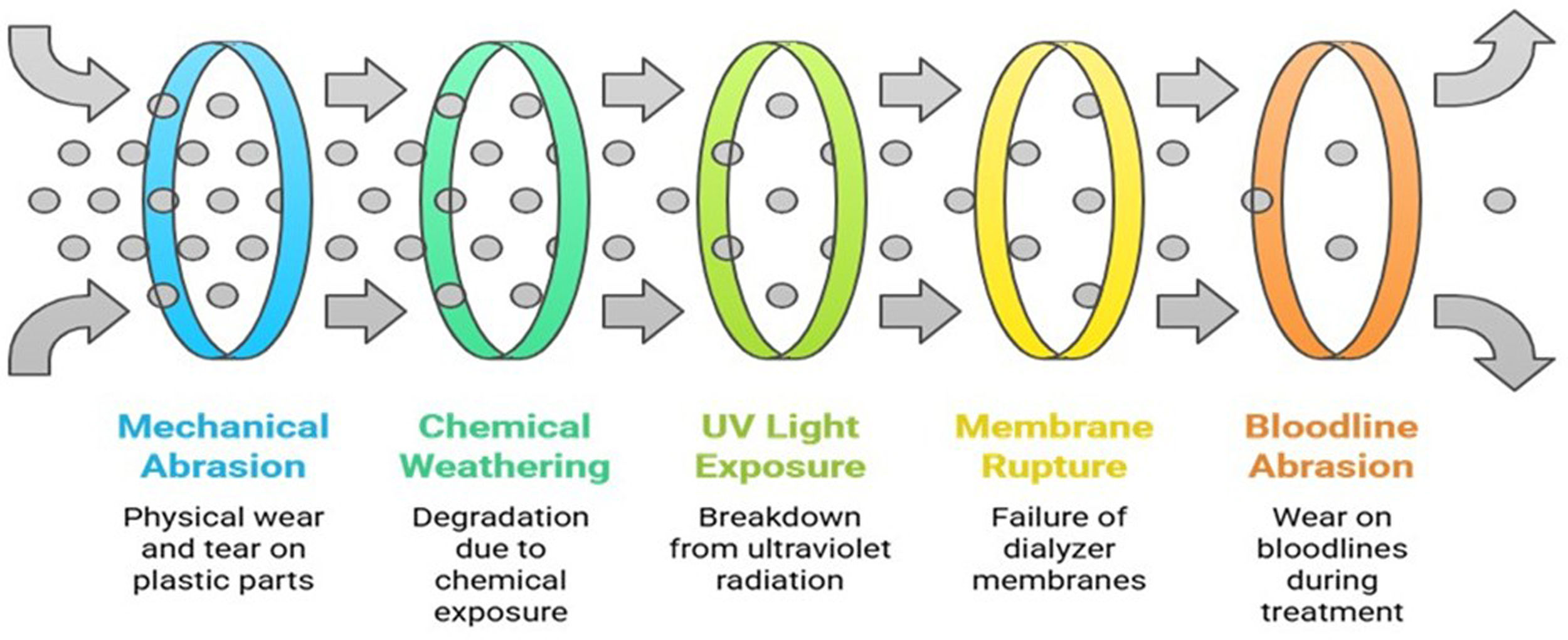

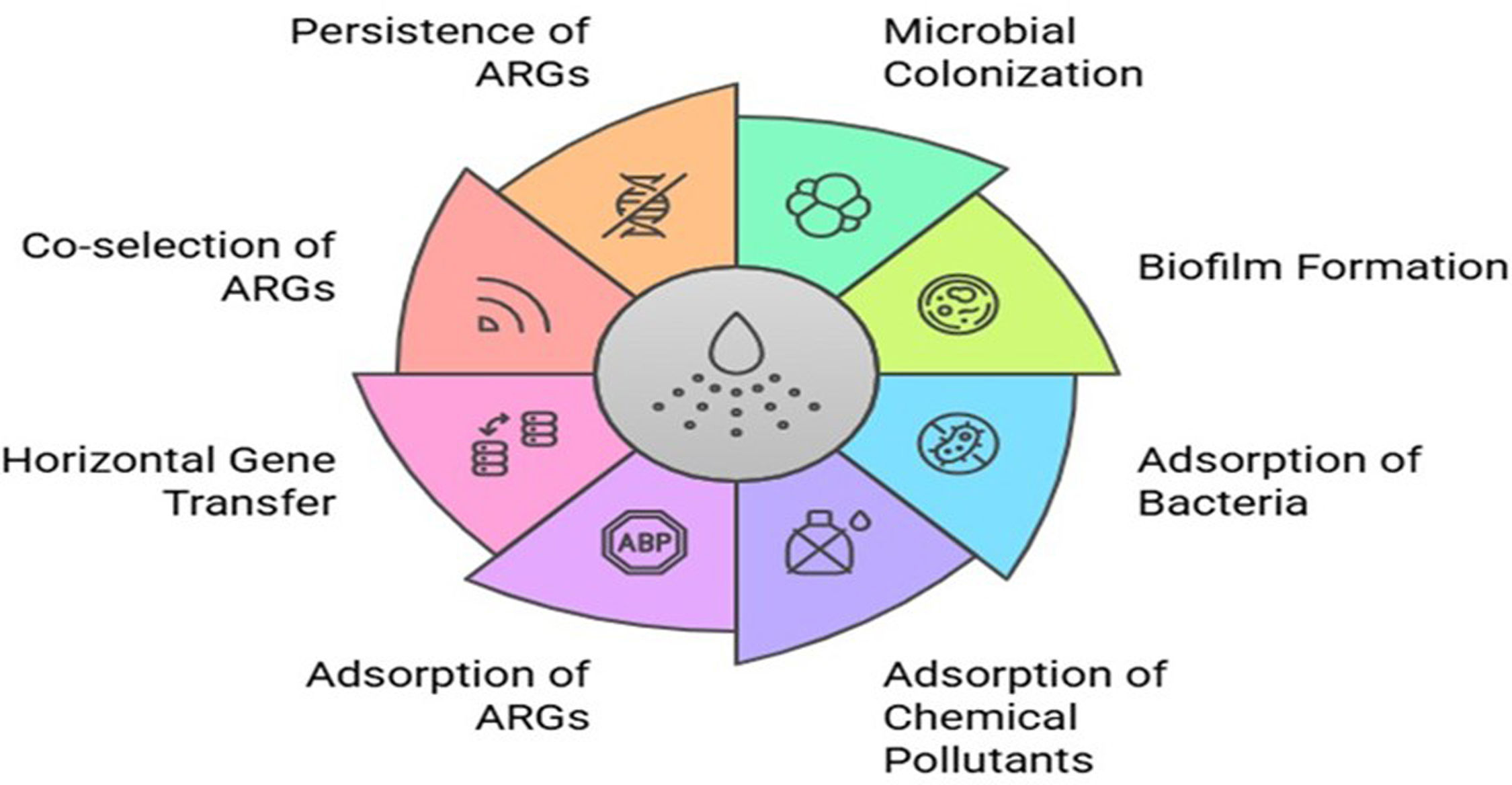

Composition and ecotoxicological risksSpent dialysate is characterized by high salinity, moderate levels of ammonia nitrogen and orthophosphates, low BOD, and minimal bacterial contamination.1,2 However, its environmental impact is complicated by emerging contaminants. ARGs, such as erm (36) and mtrD-02, along with antibiotics like betalactams, fluoroquinolones, and aminoglycosides, have been detected in dialysis sewage, highlighting potential risks for the spread of antimicrobial resistance in wastewater ecosystems.6–8 Similarly, PFAS compounds such as PFOA and PFOS have been detected at levels that necessitate stringent management to mitigate their environmental persistence.4 Micro- and nanoplastics, resulting from equipment wear (e.g., membrane rupture, bloodline abrasion), further complicate disposal,5 acting as vectors for ARGs and resistant bacteria9 (Figs. 1 and 2). Ecotoxicological studies underscore moderate ecological risks. Tests on Daphnia magna and Euglena gracilis reveal acute EC50 values of 86.91% and 76.90%, respectively, dropping to 25% under chronic exposure, indicating cumulative toxicity.7 High nutrient concentrations risk eutrophication if untreated, with potential to disrupt aquatic ecosystems. These findings highlight the need for advanced treatment to mitigate environmental impacts while enabling resource recovery.

Treatment technologiesThe literature identifies two primary treatment approaches for spent dialysate: membrane-based technologies (RO and nanofiltration) and electrochemical oxidation. RO and nanofiltration achieve >95% removal of salinity, pathogens, PFAS, and ARGs, with energy consumption of 0.5–1.2kWh/m3.2,10,11 Their cost-effectiveness (OPEX: $0.7–0.75/m3) and scalability make them preferred for large-scale hemodialysis facilities.2 In contrast, electrochemical oxidation removes 60–70% of salinity and nitrogen but incurs higher costs (OPEX: $1.13–1.31/m3) and is less efficient for demineralization.12–14 The choice of technology depends on dialysate composition and facility priorities, with membrane-based methods favored for their proven performance and lower operational costs.

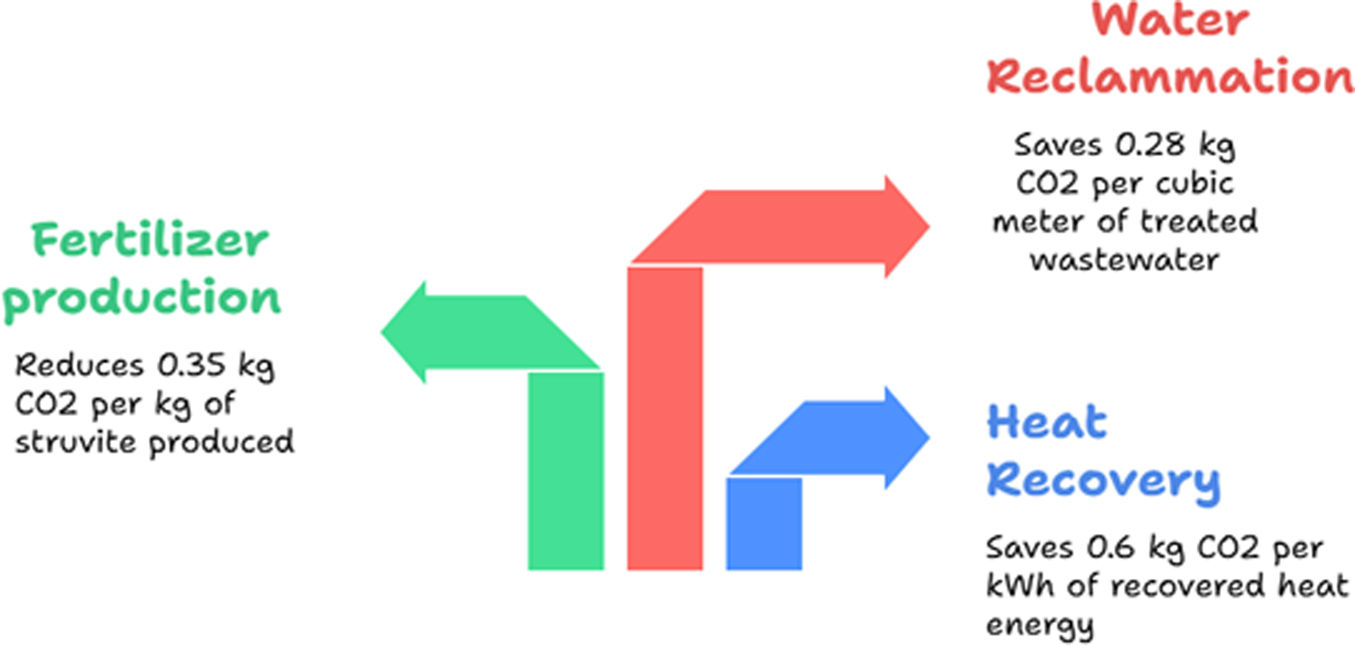

Resource recovery opportunitiesWater reclamationRO and NF produce high-quality water suitable for on-site reuse, directly reducing a facility's freshwater demand and associated environmental impact.2,10,11 This reclaimed water is ideal for non-clinical applications such as sanitation and cooling. For a standard 20-station unit, this translates to saving over 1 million liters of municipal water annually while concurrently avoiding the emission of approximately 280kg of CO2, a saving of 0.28kg per cubic meter treated compared to conventional water production.1

Nutrient recoverySpent dialysate's nutrient profile, rich in ammonia nitrogen and orthophosphates, resembles human urine, enabling recovery via struvite crystallization.1,15 A 20-chair hemodialysis facility operating two shifts daily can produce 2.4kg/day of struvite, sufficient to fertilize 5ha of arable land, with a CO2 saving of 0.35kg/kg compared to synthetic fertilizers.1,15 This recovered struvite is a valuable slow-release biofertilizer, with potential revenue streams estimated at $0.5–$1/kg.15 To ensure this value is realized and to align with circular economy principles, establishing a reliable local market is crucial. Furthermore, adopting robust quality assurance protocols is essential to guarantee product safety and build market confidence; this includes monitoring for potential contaminants, a standard practice for recovered materials that is well-documented in the literature.22

Energy recoverySpent dialysate retains thermal energy (20–25°C), with global dialysis units losing an estimated 1600GWh annually, which is equivalent to heating 140,000 homes or saving 118 million euros in fuel costs via heat exchangers, with CO2 savings of 0.6kg/kWh compared to fossil fuel-based energy.1,15 Applied to a single 20-station unit, this could represent a recoverable thermal energy potential of approximately 25–50MWh/year, depending on climate and operational hours. MFCs leverage the effluent's high conductivity to generate 0.3–0.5W/m2 of electricity.16 These technologies enhance the sustainability of hemodialysis operations.

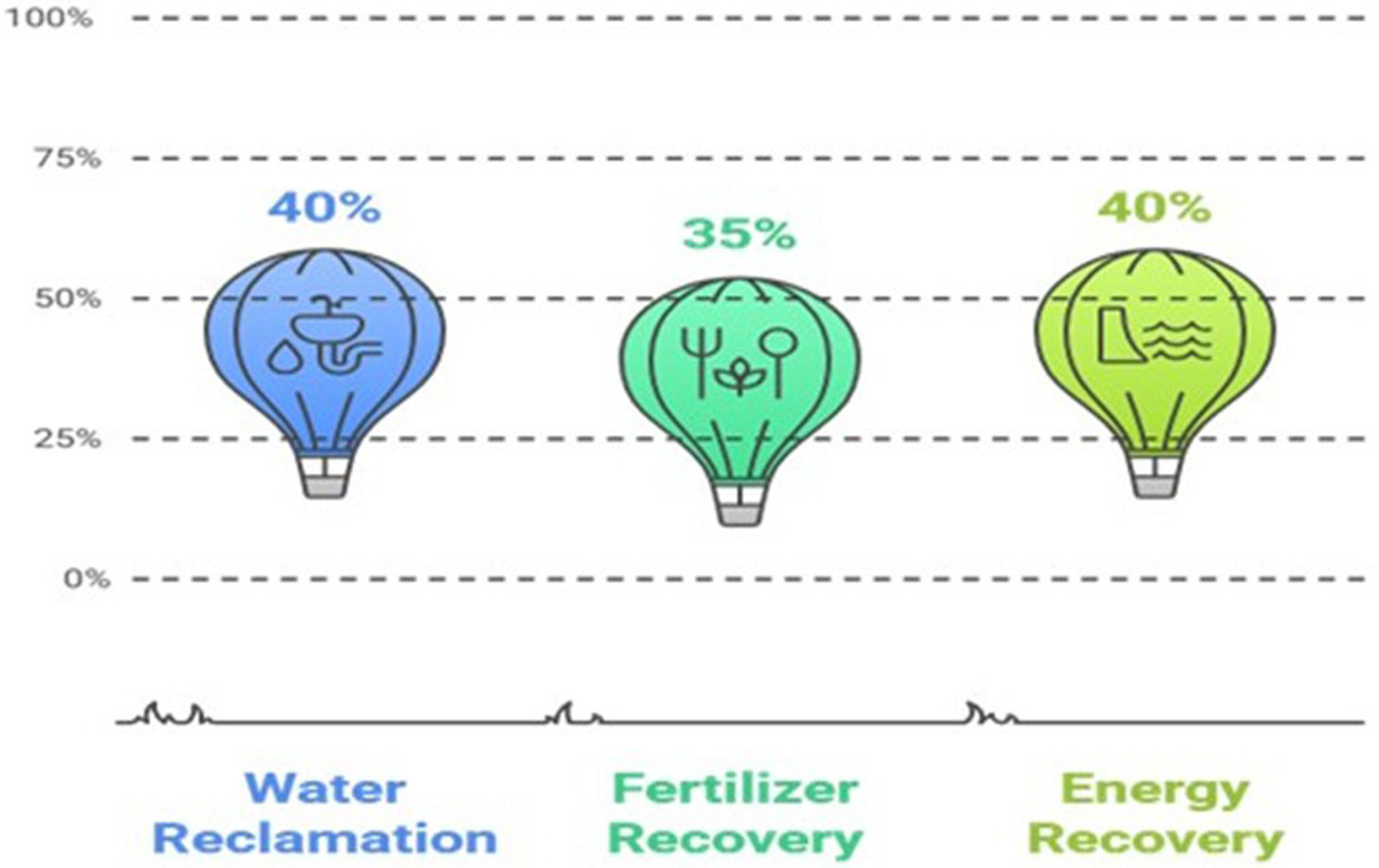

Environmental and economic impactsAdopting a circular economy model for spent dialysate can reduce environmental impacts by an estimated 30–50% compared to conventional linear disposal, as illustrated in Fig. 3.17–19 This reduction is achieved through multiple pathways: water reclamation (saving ∼0.28kg CO2/m3), energy recovery (avoiding ∼0.6kg CO2/kWh), and nutrient recycling via struvite production (saving ∼0.35kg CO2/kg)1 (Fig. 4). A significant additional benefit is the mitigation of potent methane emissions that would otherwise result from the anaerobic digestion of organic matter in wastewater, preventing an estimated 0.48kg CH4/kg BOD.20,21 Economically, these strategies translate to net cost reductions of 15–25% for facilities, stemming from lower utility and waste management expenses and potential revenue from struvite sales. While the precise figures are literature-based estimates subject to variation based on local conditions and technological scale, the compelling synergy of environmental and economic benefits firmly positions spent dialysate management as a pioneering model for sustainable healthcare.

Despite its potential, several challenges persist. High initial capital costs for RO, NF, and energy recovery systems limit adoption, particularly in smaller facilities and satellite units which lack the space and capital budgets of large hospital-based centers. Recent analyses suggest that next-generation polymeric membranes with antifouling properties could improve the long-term economic feasibility of closed-loop systems.23 Regulatory frameworks often fail to address spent dialysate's unique composition, creating uncertainty around the classification of reclaimed water and recovered products like struvite, and necessitating tailored policies. The environmental impact of dialysis-derived microplastics and ARGs remains underexplored, requiring long-term ecotoxicological studies. Scaling up resource recovery demands specialized infrastructure, staff training for new operational protocols, and supply chains for struvite and energy markets. Future research should prioritize: (1) Techno-economic assessments for different facility sizes and settings; (2) Long-term ecotoxicological studies on microplastics and ARGs; (3) Development of standardized regulatory guidelines for spent dialysate valorization; and (4) Pilot-scale demonstrations to validate operational feasibility and real-world benefits.

ConclusionThe literature underscores the transformative potential of spent dialysate as a resource within a circular economy framework. Advanced treatment technologies like RO and nanofiltration, coupled with struvite crystallization and energy recovery, enable the valorization of water, nutrients, and energy, reducing environmental impacts by 30–50% and generating economic benefits. However, challenges such as high costs, regulatory gaps, logistical barriers, and emerging contaminants like microplastics and ARGs highlight the need for further research and policy support. By addressing these barriers through targeted research, pilot projects, and collaborative policy development, spent dialysate can serve as a model for sustainable healthcare, aligning environmental, economic, and clinical goals.

FundingAuthors declare any interest, financial support or relationship that may pose a conflict of interest.

Conflict of interestThe authors declare that they have no conflict of interest.