Scarcity of water and energy, and legal requirements for discharge of waste and wastewater are forcing hemodialysis facilities to change their approach to a more integrated concept of connecting the residual output (in terms of waste, wastewater and energy loss) to the input (in terms of water and energy). Zero liquid discharge is an expanding water treatment philosophy in which hemodialysis wastewater is purified and recycled, leaving little to no effluent remaining when the process is complete, thereby saving money and being beneficial to the environment. This article explores the possible ways to treat hemodialysis wastewater, thus achieving ZLD conditions.

La escasez de agua y energía, y los requisitos legales para la descarga de desechos y aguas residuales están obligando a las instalaciones de hemodiálisis a cambiar su enfoque hacia un concepto más integrado de conectar la salida residual (en términos de desechos, aguas residuales y pérdida de energía) con la entrada (en términos de agua y energía). La descarga de líquido cero es una filosofía de tratamiento de agua en expansión en la que las aguas residuales de hemodiálisis se purifican y se reciclan, dejando poco o ningún efluente cuando se completa el proceso, lo que ahorra dinero y es beneficioso para el medio ambiente. Este artículo explora las posibles formas de tratar las aguas residuales de hemodiálisis, logrando así las condiciones de descarga de líquidos cero.

In the arid and semi-arid zones water resources of good quality are becoming more and more scare and are allocated with priority to urban water supply.1 Hemodialysis facilities are significant users of water.2 Conventional thrice-weekly 4-h haemodialysis, with a dialysate flow of 500ml/min, and a standard osmosis, consumes about 20,000L of water per year.3 In the context of a centralised preparation system, the water demands of haemodiafiltration are 10–30% higher, depending on the exchange volumes employed.3 The hemodialysis population currently estimated at approximately 2 million patients worldwide would use more than 50 millions cubic meter of water per year.4 In the United States, over 500,000 patients are receiving hemodialysis treatment and consuming yearly approximately over than 9.4 millions cubic meter of fresh water.4 In our country, Morocco, experiencing high water stress, water use by hemodialysis facilities exceeds 0.6 millions cubic meter per year.4

In hemodialysis, wastewater is generated in large quantities. One of the main environmental problems caused by the effluents is their discharge to the urban sewer network, especially in cities without sewage treatment. Wastewater generated by hemodialysis may have a significant impact on the environment due to its high salinity, turbidity, and chemical oxygen demand.5,6 The risk resulting from this discharge into bodies of water remains under-explored. However, direct discharge into aquatic ecosystems continues to be an important area of concern because of the potentially ecotoxic impact on receiving water biota.6

Scarcity of water and energy, and legal requirements for discharge of waste and wastewater are forcing hemodialysis facilities to change their approach to a more integrated concept of connecting the residual output (in terms of waste, wastewater and energy loss) to the input (in terms of water and energy).2,4,7,8 Zero liquid discharge (ZLD) is a strategic wastewater management system that guarantees to reduce the discharge of wastewater into the environment. It is achieved by treating wastewater through recycling and reuse, thereby saving money and being beneficial to the environment.9,10 ZLD projects are uncommon in hemodialysis; however, different methods can be employed to achieve ZLD. This article explores the possible ways to treat wastewater, thus achieving ZLD conditions.

First issue: recycling reverse osmosis reject waterIn the current worldwide hemodialysis practice, considerable reject water is lost to drain. A typical reverse osmosis system commonly reject 25% of water presented to them.2 Reject water is remarkably good water. It does not at any stage come into contact with the patient and therefore poses no infection risk.11 As a result, dialysis facilities must be wise to pay attention to their water wastage, and particular consideration should be given to the possibility to benefit from this reject water.

The decision to how effectively use the reverse osmosis reject water depends upon a numerous parameters such as the volume of water, its composition (salt and ions concentration), the location of the hemodialysis facility, and also the financial constraints. There are a wide range of potential uses for RO reject water within a hospital setting. Reuse opportunities are toilet flushing, garden watering, cooling water for sterilisers, etc.2 In our Mediterranean region, the reuse of reclaimed wastewater for irrigation of landscape, public parks, sport fields and recreational sites is widely spread.2,5,12

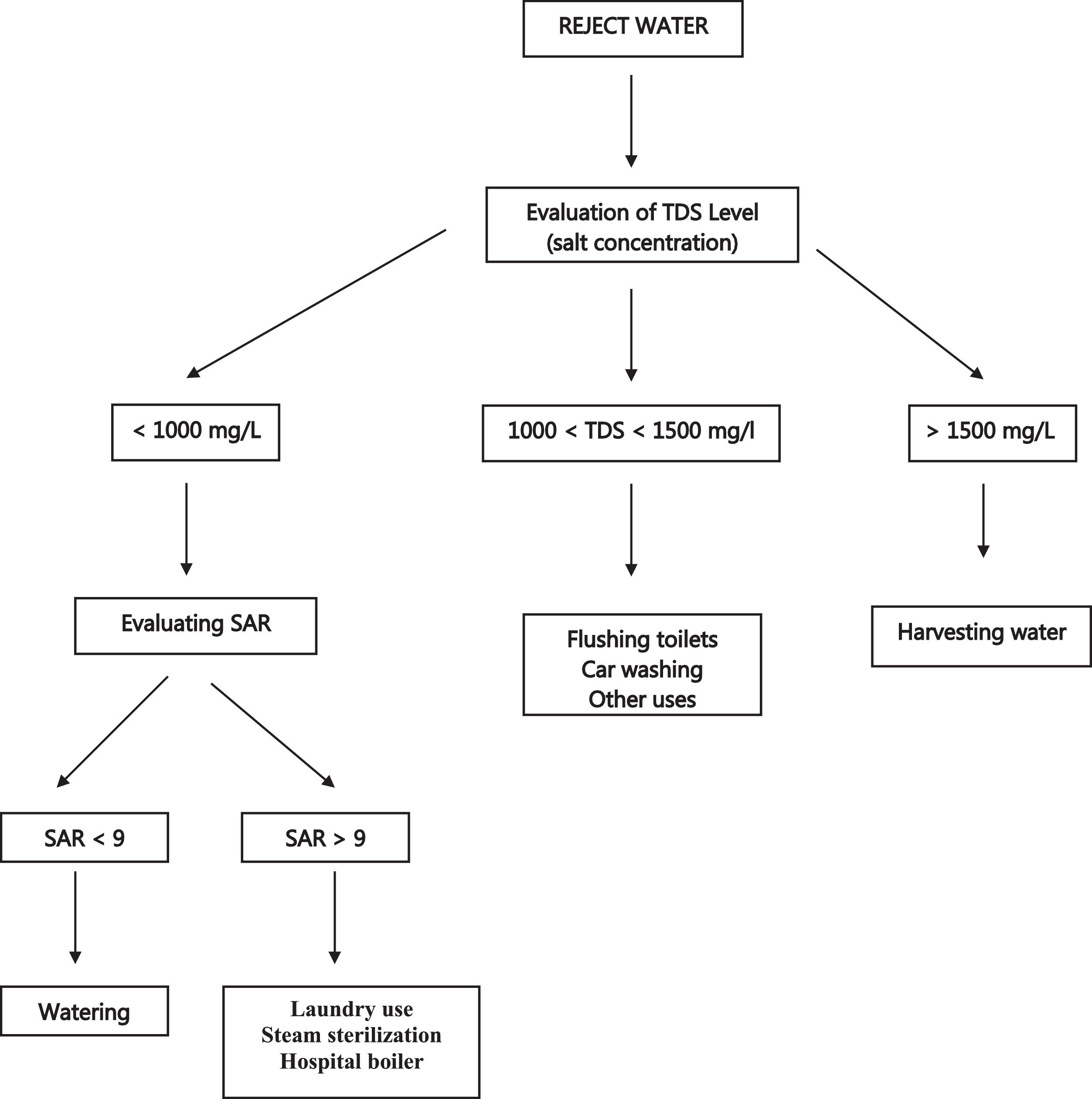

Before reusing the wastewater, it is better to check the total dissolved solids (TDS) level in water. The TDS is commonly referred to as the total dissolved minerals in water, basically compounds (salts) of Calcium, Magnesium and Sodium. TDS of the rejected water depends on the TDS of the inlet water. Water softening does not reduce TDS. In water softening, sodium replaces calcium and magnesium, in the dissolved solids, so no reduction in TDS can be seen. Water with TDS below 1000mg/l is permissible for irrigation purposes; too much TDS can reduce or prohibit crop production.13 Water with a TDS level of 1000–1500mg/l can be safely used for other purposes such as flushing toilets or car washing.14 In cases where the salt content is much higher than 1500mg/l, a simpler route would be to harvest rainwater which will dilute the salts progressively.15

If irrigation is chosen as a possible reuse option for reject water, the sodium concentration must be also evaluated. High levels of sodium in water can damage soil structure by reducing its permeability leading to problems with crop production.16 The more common method, for evaluating the sodium content in water is the measure of the Sodium Adsorption Ratio (SAR), which is the proportion of sodium (Na) ions compared to the concentration of calcium (Ca) plus magnesium (Mg).16 In general, a SAR value below 9 is considered safe for most gardening or lawn irrigation situations, while levels above 9 can cause severe problems in some soil types over time.16,17 A proposed algorithm on reuse applications based on reject water characteristics is reported in Fig. 1.

Second issue: reusing spent dialysis effluent waterSpent dialysis effluent, highly saline water, is uniformly drained to the sewer by all dialysis services worldwide. This grey water is in fact too valuable to waste, due to it reuse potential for irrigation.5,12 In Morocco, we had assessed the chemical suitability and the microbiological safety of this water, and compared it with the agricultural wastewater standards of both the World Health Organization and the United Nations Food and Agriculture Organization. With the expected exception of the sodium and chloride concentration, and thus its conductivity, the chemical analysis, levels of organic matter and bacterial counts were well within the limits of both standards.5,12

Membrane technologies, such as reverse osmosis and nanofiltration along or coupled with ultrafiltration to treat hemodialysis effluents for reuse appears to be a sustainable very promising solution, with limited materials consumption and a small energy footprint.18 Such processes in combination with biological treatment provides a reliable single barrier for bacteria and viruses and enables to efficiently handle fluctuating amounts of water while complying with stringent regulatory requirements.19–21

A wide variety of membrane materials and configuration including hollow fine fibers from cellulosic or non cellulosic materials, composite aromatic polyamide membranes in spiral wound configuration could be used for the spent dialysis effluent water treatment. While cellulose acetate membranes have a specific permeate flux of 0.5L/(m2hbar) and a salt rejection of 98.8%, the latest polyamide membranes have a specific flux of more than 1.2L/(m2hbar) and a salt rejection of 99.8%.22 Actually improvement in specific flux translates into a significant reduction of the specific energy demand.22

Third issue: regeneration of dialysate fluidConventional haemodialysis with single pass of dialysate requires approximately 150l of treated water per session. In an attempt to reduce this volume and thereby to meet the requirements for a portable artificial kidney, several attempts have been made to recycle a small volume of dialysate for reuse, making a dialysis system with a small volume of recirculating dialysis fluid possible. Until now, the REcirculation DialYsis (REDY) sorbent system, which contains urease (derived from jack beans and physically immobilized on aluminum oxide (Al2O3)) for enzymatic conversion of urea, is the only dialysate regeneration system that has been marketed.23 From 1973 to 1994, more than six million treatments were successfully performed with this transportable (approximately 20kg) dialysis system, demonstrating the clinical feasibility of HD with dialysate regeneration.24 However, manufacturing of the REDY sorbent system was discontinued in 1994. The relatively high costs of the disposable sorbent cartridges, inferior treatment adequacy compared to single-pass dialysis as a result of limited dialysate flow rates (max. 250mL/min) and concerns about aluminum-induced osteomalacia and dementia may have contributed to this.24

Benefits from zero liquid discharge in hemodialysisFinancial savingsFinancial costs of a ZDL project are widely variable because they are dependent on site-specific factors. Financial costs are influenced by size, location, incoming water quality, extent of transmission lines and pumping requirements, timing and storage requirements, costs of energy, and the complexity of the permitting and approval process. Capital costs in particular are site specific and can vary markedly from one project to another.

Data on reuse costs are limited in the published literature. Connor et al.25 had studied the saving potential of a 800l per hour redirecting reverse osmosis reject water system for flushing toilets. The initial set-up costs included a feasibility study, materials (piping and one holding tank) and installation costs. The system allowed to recovering costs in less than three years, with a 38% reduction in the use of mains water and a saving potential of 9500 USD each year.

The economic feasibility of the treatment of spent dialysis effluent was analyzed by our group.5,12 The main advantage of treating spent dialysis effluent is that it is cheaper and the energy demand is lower than for seawater desalination for landscaping purposes. The cost for treating spent dialysis effluent to achieve quality suitable for irrigation using nanofiltration and reverse osmosis is 0.70USD/m3 and 0.74USD/m3, respectively. Given the average cost of 1USD/m3 for seawater desalination, this could result in cost savings (or benefit) of 20–30% in comparison to desalination of seawater.

Environmental impactEvery drop of water conserved reduces energy consumption and associated carbon emissions. Water use means energy use, therefore conserving water means conserving energy.26,27 Electricity consumption associated with water use results from the energy required to pump, treat water, and to operate machines that use water in homes and businesses. Energy savings from water conserved will help reduce air pollution and limit greenhouse gas emissions associated with energy production.

The carbon footprint of kidney care is high and estimated to be 27 million tonnes of carbon dioxide per year worldwide, around 5 million tonnes of CO2 in US, and 0.3 million tonnes per year in our country, Morocco (0.5% of all greenhouse gas emissions in the country).4 The amount of carbon saved by use of the reject hemodialysis water remains unknown. In the United Kingdom, Connor et al.25 reported that the use of 14.5m3 of reject hemodialysis water per day in place of tapwater can result in saving 1240kg of CO2 equivalents per year. Accordingly, the estimated carbon saving could be estimated to be about 0.28kg of CO2 per 1m3 of reused reject water.

ConclusionHemodialysis is faced with many challenges due to high resource (energy and water) consumption, footprint emission and its consequent impact to the environment. The implementation of ZLD systems in hemodialysis facilities will help to reduce wastewater economically and produce clean water that is suitable for reuse (e.g. irrigation), thereby saving money and being beneficial to the environment.

Conflict of interestThe authors declare that they have no conflict of interest.