A Best Practice Guideline about Dialysis fluid purity was developed under the leadership of the Spanish Society of Nephrology in 2004. The second edition revised Guideline considered new evidences and International Standard. The guideline has established recommendations for standards for preparing dialysate: water, concentrates and haemodialysis proportioning systems. This guideline is based on the ISO 13959, European Pharmacopoeia, the Real Farmacopea Española, the AAMI Standards and Recommended Practices, European Best Practice Guidelines for Haemodialysis, literature reviews, according to their level of evidence, and the opinion of the expert Spanish group.

Two levels of quality of water were defined: purified water and high purified water (ultra pure) and for dialysate: ultra pure dialysate. Regular use of ultra pure dialysate is recommended for all type of haemodialysis to prevent and delay the occurrence of complications: inflammation, malnutrition, anaemia and amiloidosis.

Water, concentrates and dialysate quality requirements are defined as maximum allowable contaminant levels: chemicals (4.1.2), conductivity, microbial and endotoxins (4.1.1):

Monitoring frequency, maintenance and corrective actions were specified. Methods of sampling and analysis were described in Appendix. For microbiological monitoring, R2A medium is recommended, incubated during 7–14 days at a temperature of 17–23°C.

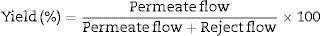

The dialysate quality assurance process involves all dialysis staff members and requires strict protocols. The physician in charge of haemodialysis has the ultimate responsibility for dialysate quality.

All suggestions and questions about this Guideline are welcome to www.senefro.org.

La Sociedad Española de Nefrología elaboró en 2004 una Guía de Gestión de Calidad del Líquido de Diálisis. La segunda edición revisada de la guía ha tenido en cuenta nuevas evidencias y la normativa internacional. En la guía se hacen algunas recomendaciones sobre normas para preparar el líquido de diálisis: agua, concentrados y sistemas de dosificación de la hemodiálisis. Esta guía se basa en la norma ISO 13959, la Farmacopea Europea, la Real Farmacopea Española, las normas y prácticas recomendadas de la AAMI, la Guía Europea de Buena Práctica en Hemodiálisis, revisiones de la bibliografía, según su nivel de evidencia, y la opinión del grupo español de expertos.

Se definieron 2 niveles de calidad del agua: agua purificada y agua purificada de alta calidad (ultra pura), y para el líquido de diálisis: líquido de diálisis ultra puro. El uso habitual de líquido de diálisis ultra puro se recomienda en todo tipo de hemodiálisis para prevenir y retrasar la aparición de complicaciones: inflamación, desnutrición, anemia y amiloidosis.

Los requisitos de la calidad del agua, de los concentrados y del líquido de diálisis se definen como los niveles máximos admisibles de contaminantes: sustancias químicas (4.1.2), conductividad, microbiana y endotoxinas (4.1.1):

Se especificaron la frecuencia de control, el mantenimiento y las medidas correctivas. Los métodos de muestreo y análisis se describieron en los anexos. Para el control microbiológico es recomendable el medio de cultivo R2A, incubado durante 7–14días a una temperatura de 17–23°C.

El proceso de garantía de la calidad del líquido de diálisis implica a todos los miembros del personal de diálisis y exige protocolos estrictos. El médico a cargo de la hemodiálisis tiene la responsabilidad final de la calidad del líquido de diálisis.

Pueden dirigir sus sugerencias y preguntas acerca de esta guía a www.senefro.org.

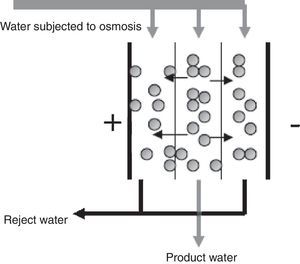

Dialysate or dialysis fluid (DF) is one of the basic elements of haemodialysis (HD). It is a liquid medium which comes into contact with the blood through the semipermeable membrane in the dialyser during haemodialysis. It allows the exchange of substances, essentially solutes, with the blood, in both directions.

It is an electrolyte solution prepared extemporaneously by the haemodialysis machine (HDM) from purified water and solutes provided in the form of electrolyte concentrates or undissolved salts. Prepared in this way, dialysate is virtually isotonic and its electrolyte composition is similar to plasma. There are differences in the concentrations depending on the gradients necessary to achieve the appropriate balance of each substance according to the needs of the patient.

Dialysate quality and purity are two of the most critical requirements of haemodialysis. The presence of contaminants in the dialysate exposes the patient to the risk of toxic substances accumulating and consequent acute and chronic complications. Some contaminants can interact with cells or proteins, triggering bio-incompatibility on top of that caused by other components of the extracorporeal blood circuit in haemodialysis.

Dialysate quality and purity are the result of a complex series of processes in which any error has a huge impact on the final product. It is therefore necessary to monitor all the elements and steps involved in the entire production chain. The preparation, distribution and storage conditions must be designed to minimise the risk of chemical and microbiological contamination.

For ease of understanding, this guideline consists of six key subject areas:

- 1.

Water treatment systems (Section 4 and Appendix A.2.1).

- 2.

Electrolyte concentrates and powdered salts (Section 5 and Appendix A.2.2).

- 3.

Haemodialysis machine (Section 6.3 and Appendix A.2.3).

- 4.

Quality control (Section 7 and Appendices 3 and 5).

- 5.

Methods for correction and prevention (Section 8 and Appendix 4).

- 6.

Dialysate quality management (Section 9).

The guide includes: a glossary of terminology with references to the corresponding sections (Section 2); a quick guide with the standards (in bold) and key recommendations, divided into six sections (Sections 4–9); Section 10 with the rationale and evidence supporting the recommendations (Section 10); and Appendices 1–6 describing equipment components and methodology.

Introduction to the 2015 editionThe purpose of this first revision of the Sociedad Española de Nefrología (SEN) [Spanish Society of Nephrology] Guideline for Dialysate Quality (GDQ), published in Nephrology 2004;24 Suppl. 2:1–42, is to update it and bring it into line with haemodialysis today.

It is 11 years since the 1st edition of the GDQ and haemodialysis has evolved:

- 1.

Most haemodialysis (HD) in our area is high-flux (80–90%) and the proportion of patients on on-line haemodiafiltration (OL-HDF) has increased significantly (20–30%). Today's HD requires ultrapure dialysate.

- 2.

HD water treatment technology has also evolved. The effective treatment systems available these days for the water used in HD maintain fairly uniform standards.

- 3.

Although many of the HD water treatment systems in Spain have been renewed and improved, contamination above the specified limits continues to occur; mainly microbiological or involving aluminium and chloramines. Prevention of contamination must therefore be a goal.

- 4.

Maintaining the standard of highly purified water continues to create technical problems in many HD units. Certain requirements for highly purified water need to be refined or modified without affecting the requisite quality.

- 5.

Aspects relating to dialysate quality not covered in the first edition need to be included, such as feed water supply characteristics, testing methods for certain contaminants, portable and home water treatment systems and monitoring of central concentrate delivery systems.

The GDQ has set the standard to be followed in terms of HD water and dialysate quality in Spain and other countries. Many of the Spanish Autonomous Regions have used it for their technical specifications and agreements for HD. The Ministry of Health, Social Policy and Equality included it as a reference in its Standards and Recommendations for extrarenal blood purification (haemodialysis) units in 2011. The GDQ helped create a culture of awareness about the importance clinically of ultrapure dialysate, which was subsequently endorsed by a large volume of scientific evidence. It has been pioneering in a number of ways, one being that the microbiological testing methodology proposed in the 2004 GDQ is similar to that of the 2014 ISO 13959.

We have attempted to make the terms of this guideline more readily understandable and interpretable. We have therefore standardised the terminology used, as described in Section 3.3.

The GDQ was commissioned to a group of experts by the SEN. This revision has been commissioned by the present SEN Board of Directors, chaired by Dr Maria Dolores del Pino, to a new group of experts.

2Glossary of terms and definitions- AAMI:

Association for the Advancement of Medical Instrumentation: Recommends standards for medical procedures in the United States of America. www.aami.org. See Appendix 6.

- Action level:

Degree of contamination at which implementation of corrective measures is recommended to avoid reaching unacceptable contamination limits. See Section 4.1.1.

- Activated charcoal filter:

Filter used to remove chlorine, chloramines and organic substances from water by means of adsorption onto the microporous structure of the activated charcoal. See Appendix A.2.1.

- Actual volume of a bed:

The volume of a bed in a container. The space between the particles is considered as volume occupied by the bed itself. See Appendix 2.

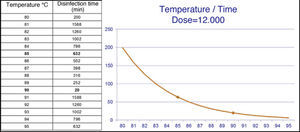

- Ao:

Ao is a way of calculating the “dose of thermal energy necessary” to disinfect, based on different combinations of time and temperature. One Ao equals one second at 80°C. (1 Ao=1second at 80°C). Ao=∑10 (T−80)/z·Δt, where T is temperature in °C; z equals 10°C; and Δt is the time in seconds. See Section 8.

- Backwash:

Process for a bed filter consisting of introducing water from the bottom to flow upwards to expand the bed and allow removal of retained particles. To be effective, the water velocity should be slightly greater than the fluidisation velocity to achieve expansion of the bed by at least 10%. See Appendix 2.

- Bed expansion:

Increase in the bulk volume of a bed when subjected to a backwash cycle. See Appendix 2.

- Bed filter:

Filter consisting of a container filled with a rigid material of uniformly sized granules that retains particles in the free spaces. Backwashes are necessary to remove retained particles. See Appendix 2.

- Biofilm:

Colonies of bacteria settled on the surfaces of hydraulic circuits, protected by an ecosystem of precipitated minerals and an extracellular mucopolysaccharide matrix, which reproduce and generate in stagnant conditions. The presence of biofilm is associated with persistent bacterial contamination. It is an active source of endotoxins and other biologically active bacterial derivatives. It is resistant to the majority of disinfectants. See Appendix 3.

- Buffer tank:

Tank installed at the beginning of a water treatment plant to provide a constant flow rate. Its function is not to store water, but to stabilise the process and not depend on the feed water supply pressure. See Appendix 2.

- Bulk volume of a bed:

The volume of a bed when expanded with a backwash cycle. See Appendix 2.

- Cartridge filter:

Consists of a cylinder of porous material which retains particles smaller than the pore size when water is passed through it. See Appendix 2.

- Chemosynthetic bacteria:

Bacteria capable of synthesising their nutrients and obtaining energy from inorganic compounds. See Appendix 2.

- Chloramines:

Products formed by the combination of free chlorine and ammonium. The ammonium can come from decomposition of vegetable matter and other organic pollutants, or be added by those responsible for the water's potability in order to disinfect it. Chloramines are extremely oxidative and toxic for patients on haemodialysis. See Appendix 5.

- Colony-forming units (CFU):

Unit of measurement of viable bacteria. Refers to the number of bacterial colonies which have developed in a solid culture medium. Expressed as CFU per millilitre of fluid. See Appendix 3.

- Combined chlorine:

Chlorine chemically bound to other compounds, like chloramines. Total chlorine equals free plus combined chlorine. See Appendix 5.

- Concentrates for dialysis:

Concentrates or salts to be mixed with the purified or highly purified water in the haemodialysis machine to form the dialysate. These concentrates or salts are manufactured, packaged and labelled to CE marking standards and must comply with ISO 13958. See Section 5.

- Conductivity:

Measure of a material ability to conduct an electric current and is the inverse of resistivity. The concentration of electrolytes in water is directly related to the electrical conductivity of the solution. It is measured in Scm−1. See Section 10.8.

- Continuous electric deionization (CDI) or electro-deionization (EDI) system:

Device for reducing the concentration of free ions in the water, cations and anions, applying an electric field. See Appendix A.2.1.

- Deioniser (DI):

Device for reducing the free ions in the water, with dual-bed or mixed-bed cationic and anionic resins. See Appendix 2.

- Dialysate:

Aqueous fluid containing electrolytes, buffers and usually glucose, which is formed by combining water and dialysis concentrates and salts in the dialysis machine. The terms dialysis fluid, dialysis solution or dialysis bath are synonymous. See Section 6.

- Dialyser:

Haemodialysis machine in which the dialysis takes place by way of diffusive and convective transport and adsorption. Inside, the blood and dialysate come into contact through a semipermeable membrane. Also called a filter.

- Disinfection:

Process for destruction of microorganisms, which reduces their numbers but does not eliminate them. Sterilisation reduces the numbers to a safe level, since total elimination is virtually impossible. Can be done by chemical or thermal means. See Section 8.

- Electro-medical equipment:

Active non-implantable medical device (ANIMD) and as such, subject to European and national regulations (i.e. RD1591/2009, Medical Devices Directive, 93/42/CEE, ISO13485, IEC 60601.1:2015). See Appendix 6.

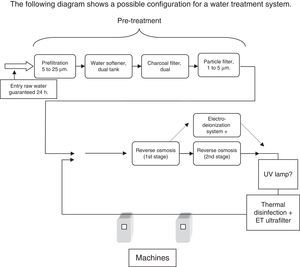

- Empty Bed Contact Time (EBCT):

Contact time between the water and the activated charcoal bed. Calculated by the equation EBCT=(7.48*V)/Q, where V is the bulk volume of the bed and Q the water flow expressed in gallons/min. See Appendix A.2.1.

- Endotoxin units per ml (EU/ml):

Units of endotoxin (ET) quantified by a test based on Limulus amoebocyte lysate (LAL) activation. ET activity varies according to its composition, so its activity is compared to the E. coli standard (O 113: H10). The relationship between the activity and the mass varies with the batch of LAL and batch of ET standard. Generally, 0.012 endotoxin units are equivalent to approximately one picogram. The ratio is generally 10 EU per ng. Chromogenic determination is the most sensitive, although other methods (colorimetric, fluorimetric, GEL-CLOT) are routinely used in these determinations. See Appendix A.3.2.

- Endotoxin:

Biologically active pyrogenic substance, lipopolysaccharide, released from the outer cell wall of gram-negative bacteria. They are measured in Endotoxin Units, EU/ml, or in International Units, IU/ml, which are now equivalent. See Appendix 3.

- Exotoxin:

Protein with pyrogenic activity secreted by microorganisms. See Appendix 3.

- Feed or raw water:

Feed water means the water to be treated, whether it comes from the municipal water supply, is taken from a well or is delivered by tankers. In general it is potable water, which in Spain is subject to the relevant regulations. See Appendices 1 and 5.

- Fluidisation velocity:

The velocity of backwashing of a bed filter to which the filter is subjected to an upward force equal to its weight. Its bulk volume does not vary; expansion is zero. See Appendix 2.

- Forward rinse:

Process for a filter bed consisting of introducing water at the top and removing the water used in the backwash, which has not been filtered. See Appendix 2.

- Free chlorine:

Dissolved molecular chlorine. See Appendix 5.

- Haemodiafiltration:

Form of haemodialysis in which, alongside diffusive transport, convective transport plays an important role in solute removal.

- Haemodialysis machine:

Machine or system that carries out the haemodialysis process. The dialysis process takes place in a dialyser where the blood circuit and the hydraulic circuit combine to produce the dialysate. These two circuits are controlled by the machine with maximum efficacy and safety for the patient.

- Haemodialysis:

Form of renal replacement therapy that involves the removal of solutes from the blood and exchange of solutes between the blood and the dialysate. The solutes are preferentially removed by diffusion.

- Heterotrophic bacteria:

Bacteria, which metabolically, require organic compounds to develop. This is a broad and diverse group that includes symbiotic, saprophytic and pathogenic species. The term heterotrophic is commonly used as a generic name for water bacteria with few nutritional requirements. See Appendix 3.

- ISO:

International Standardization Organization. See Appendix 6.

- Limulus Amoebocyte Lysate (LAL) test:

Specific detection assay for endotoxins, based on horseshoe crab, Limulus polyphemus, amoebocyte lysate. See Appendix 3.

- Lipopolysaccharides (LPS):

Endotoxins composed of lipids and sugars (polysaccharides). See Appendix 3.

- Microfilter:

Filter able to remove particles larger than 1μm in diameter (0.1–0.3μm according to the ISO). See Appendix 2.

- Nanofiltration:

Retains organic compounds with molecular weights between 300 and 1000 D, retains some salts and works at lower pressure than RO. See Appendix 2.

- Nominal flow rate:

The flow rate produced by reverse osmosis equipment under ideal conditions. See Appendix 2.

- Permeate or “filtrate”:

Fluid that has passed through a reverse osmosis membrane. See Appendix A.2.1.

- Pleated cartridge filter:

Cartridge filter consisting of a rigid perforated core in which the porous material is very thin and has a large surface area, “a kind of paper” folded in zigzag formation, sealed at both ends and attached to the core. The filtering capacity is determined by the porosity of the filter material. Can retain particles and bacteria up to 0.2μm. See Appendix 2.

- Pre-filter or “sediment or sand filter”:

Bed filter that removes large particles, from 500 to 20μm, positioned at the point of entry of the water into the treatment. Allows backwashing. See Appendix A.2.1.

- Pre-treated water:

Water that has undergone all the processes before reaching the osmosis or treatment equipment. See Appendix 2.

- Purified water:

Water for the preparation of drugs or dialysis fluids which do not necessarily need to be sterile or pyrogen-free. See Section 4.1 of this guideline.

- Pyrogen:

Substance that causes fever or inflammation. External pyrogens (endotoxins/exotoxins, bacterial DNA) induce cytokines such as IL-6, IL-1 or TNFα, which are mediators in the induction of fever and inflammation. Substances capable of activating mononuclear blood cells. See Appendix 3.

- Pyrogen-free sterile water:

Water free of live organisms and spores. Sterility is defined as the presence of fewer than 1×10−6CFU/ml viable bacteria or <0.03EU/ml. See Appendix 3.

- R2A:

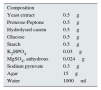

Culture medium for bacteria which, due to its high sensitivity, is particularly indicated for water contaminants. For composition see Appendix A.3.1.

- Reject or “concentrate” water:

Water that has not passed through the osmosis membranes and contains practically all the salts and contaminants. See Appendix 2.

- Resin:

Cations, anions or mixture attached to granules in ion exchange beds, such as in water softeners and deionisers. See Appendix 2.

- Resistivity:

Resistance of a material to the flow of electricity through it. It is the inverse of conductivity. The fewer the electrolytes, the greater the resistivity. Resistivity of 1MΩ/cm is the same as conductivity of 1μS/cm. See Section 10.8.

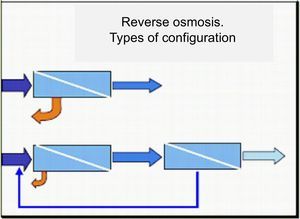

- Reverse osmosis (RO):

Water purification process which works by sieving through a membrane and rejection of ion concentrate. Removes ions and organic contaminants with molecular weight >100 D. See Appendix A.2.1.

- SDI:

Silt Density Index. Parameter that measures the density of sediments or the fouling tendency of water. Measurement of this index is regulated by ASTM International (formerly American Society for Testing and Materials). See Section 10.5.

- Substitution fluid:

Fluid or dialysate used in haemofiltration and haemodiafiltration and infused into the blood circuit to replace the ultrafiltrate. It is mandatory for this to be ultrapure dialysate and undergo a second ultrafiltration for endotoxins. It can also be used for priming and flushing the blood circuit, as bolus, as infusion during the session or in blood return. Also called infusion fluid. See Section 6.

- TDS:

Total dissolved solids. Sum of all dissolved ions. Related to the electrical conductivity and used to test the effectiveness of reverse osmosis. See Section 10.8.

- TGEA:

Culture medium for bacteria, recommended by the ISO and the European Guidelines, along with R2A. Composition: Tryptone glucose yeast extract agar. See Appendix A.3.1.

- TSA:

Culture medium for bacteria. For composition see Appendix A.3.1.

- Ultrafilter:

Membrane filter (polysulfone, polyamide, polyethersulfone, posidyne) used to remove microbial components from dialysis water, post-treatment in the dialysis water or, most commonly, in dialysis fluids. Some ultrafilters retain ET by adsorption. Also used as a synonym of dialyser. See Appendix 2.

- Ultrafiltration, as dialysis method:

Convective transport of solutes across a membrane driven by a hydrostatic pressure gradient (transmembrane pressure).

- Ultrafiltration, as treatment of dialysate:

Process similar to RO. Rejects contaminants between 1000 D and 0.1μm. Ultrafiltration requires low pressures to operate. Essentially retains organic substances, bacteria and pyrogens. The effectiveness of ultrafiltration membranes is determined as the lowest molecular weight that rejects more than 90% (Molecular Weight Cut-off [MWCO]). See Appendix 2.

- Ultrapure dialysate:

Dialysate, preferably produced with highly purified water, with fewer than 0.1CFU/ml and fewer than 0.03EU/ml which has passed through an ultrafilter immediately pre-dialyser. See Section 6.

- Ultrapure water:

Ultrapure or highly purified water is defined as water meeting the recommendations on content in chemical contaminants listed in Section 4.1.2. Maximum conductivity is 5μScm−1, measured at 25°C, bacterial contamination is less than 0.1CFU/ml (10 CFU/100ml) and endotoxin levels must be less than 0.03EU/ml. See Section 4.2.

- Ultraviolet:

Bactericidal ultraviolet radiation used to kill microorganisms. UVC, wavelength-energy-photon: 200–290nm and 6.2–4.3eV. 254nm is recommended and 16 milliwatt-s/cm2 followed by use of an endotoxin filter. ISO 13958:2009. See Appendix 2.

- USP:

United States Pharmacopoeia. See Appendix 6.

- Venting:

Entry and exit of air that occur when the volume of a liquid stored in a rigid container varies. It may have a 0.2μm filter in order that the air entering meets specifications. See Appendix 2.

- Water softener:

Device for reducing water hardness by removing the calcium and magnesium by ion exchange with cations fixed on resins. See Appendix A.2.1.

- Wound cartridge filter:

A cartridge filter formed by a rigid perforated tube or core in which the porous material consists of a cord made of cotton, polypropylene or other similar material; depending on the type of yarn, the number of threads per revolution and the winding pressure, varying filtering capacity is obtained. Can retain particles from 1 to 100μm. See Appendix 2.

- AAMI:

Association for the Advancement of Medical Instrumentation: www.aami.org

- CDI:

Continuous electric deionization or electro-deionization system

- CK:

Cytokines or interleukins

- CSA:

Canadian Standards Association

- DI:

Deioniser

- EBCT:

Empty bed contact time; contact time with the activated charcoal bed

- EDI:

Continuous electric deionization or electro-deionization system

- HD:

Haemodialysis

- HDF:

Haemodiafiltration

- OL-HDF:

On-line haemodiafiltration

- HF:

Haemofiltration

- ISO:

International Organization for Standardization

- LAL:

Limulus Amoebocyte Lysate

- DF:

Dialysis fluid (dialysate)

- LPS:

Lipopolysaccharides/Endotoxins

- HDM:

HD machine

- RO:

Reverse osmosis

- ppm:

parts per million

- TMP:

Transmembrane pressure

- R2A:

Reasoner's 2A culture medium

- SDI:

Silt Density Index

- PS:

Pyrogenic substances

- LAL test:

Limulus Amoebocyte Lysate (LAL) test

- EBCT:

Empty Bed Contact Time (contact time with the activated charcoal bed)

- TDS:

Total dissolved solids

- TGEA:

Tryptone glucose yeast extract agar

- TSA:

Bacto Tryptic Soy Agar; Soybean-Casein Digest Agar

- EU:

Endotoxin Units

- IU:

International Units of endotoxins

- CFU:

colony-forming units

- USP:

United States Pharmacopoeia

The purpose of this guideline is to provide recommendations on quality for water, concentrates and dialysate in order to ensure that haemodialysis is effectively performed. The aim of effective haemodialysis is to promote optimal treatment for patients on haemodialysis. This guideline aims to provide unified criteria on the necessary quality of water, concentrates and dialysate, along with methods for achieving and maintaining that level of quality.

3.2ScopeThe scope includes all types of haemodialysis or haemodiafiltration or any extrarenal blood purification technique that uses dialysate. Geographically, the scope of application of this guideline is the Spanish National Health Service, as it is specifically adapted to the practice of haemodialysis in Spain today. It is intended to be seen as a goal for maintaining or achieving quality in Spanish haemodialysis units, and the hope is that its recommendations will be taken on board by all healthcare workers, dialysis technicians and companies engaged in the field of dialysis.

3.3MethodologyCreation of the expert group: The Spanish Society of Nephrology appointed a nephrologist with extensive experience in haemodialysis, and coordinator of the first edition of this guideline (2004), as coordinator of this second edition; the multidisciplinary working group was then set up, including four nephrologists and other specialists, experts in various technical and scientific aspects related with water treatment, a microbiologist, four haemodialysis technicians, a product manager and a renowned researcher in the area of biocompatibility in dialysis. The multidisciplinary approach is essential to provide a comprehensive picture of the subject, not only for the theoretical aspect of the literature review, but from the perspective of experience in day-to-day practice.

Dynamics of meetings: The first meeting was to decide on the aspects to be studied and divide them among the different experts. At subsequent meetings, each expert's proposals were discussed in an effort to reach a consensus on conclusions. A final face-to-face consensus meeting was then held.

An information search was carried out, covering literature (Medline/PubMed, Cochrane) other guidelines (see Appendix 6), reports by quality control agencies and technology assessments (ISO, European Pharmacopoeia, AAMI, etc.; see Appendix 6).

Analysis of the quality of the evidence: The grading system used was Grades of Recommendation Assessment, Development, and Evaluation (GRADE) (Uhlig K et al. Grading evidence and recommendations for clinical practice guidelines in nephrology. A position statement from kidney disease: improving global outcomes (KDIGO). Kidney Inter 2006;70:2058–2065). The quality (level) of evidence (A–D) and the strength of the recommendation (1–3) were arrived at by consensus at the proposal of the authors of each chapter. The quality of water, concentrates and dialysate can at times be a special case in terms of grading level of evidence. This area has been addressed in the ISO-AAMI. In some instances in this guideline, we have adhered to the latest editions of the ISO standards in order to meet one of the main objectives, which was to unify criteria with other recommendations/international guidelines.

The terminology used in this guideline has been standardised in relation to the level of evidence or the ISO standards as follows:

- –

“shall” means that compliance with a requirement or a test is mandatory (required=strong recommendation)

- –

“should” means that compliance with a requirement or a test is recommended, conditional on what is explained for that instance (recommended=weak recommendation)

- –

“may” is used to describe a permissible way to achieve compliance with a requirement or test (permissible or not graded)

As a basic rule, any treatment system for water for haemodialysis must be designed to, at the very least, meet the specifications for chemical and bacteriological levels recommended in this guideline, including in terms of maintenance of that system over time.

Water used for haemodialysis is divided into two distinct types: standard or purified water (4.1); and ultrapure or highly purified water (4.2). Each type has different criteria for microbiological quality and endotoxins. The current position of these guidelines is to recommend that highly purified water shall be used in haemodialysis units as the main component of ultrapure dialysate.

4.1Purified water for haemodialysis4.1.1MicrobiologyMaximum allowable levels for microbiological purityIn terms of bacteriological requirements, purified water used for diluting the dialysis concentrate shall contain fewer than 100CFU/ml. ISO 13959. 3rd edition 2014.

SpecificationsThese CFU figures correspond to the average of the total number of viable aerobic bacteria able to form a visible colony for each sample spread on R2A medium and incubated for 7 days between 17°C and 23°C (ISO 13959, 3rd edition 2014).

Although there is little literature base to support it, fungi should not exceed 10% of the total colonies of aerobic organisms (Evidence level C, 2).

For additional specifications and recommendations on this section, consult Appendix A.3.1.

Action levels for microbiological purityWe recommend that corrective measures, i.e. disinfection, be commenced when bacterial counts reach 50% of the mandatory limit: presence of more than 50CFU/ml of viable aerobic bacteria ISO 13959. 3rd edition 2014. Disinfection should also be performed with lower contamination levels if visible in more than one sample in order to prevent the formation of bacterial biofilm.

Maximum allowable levels of endotoxinsThe endotoxin content in purified water for haemodialysis shall not exceed 0.25EU/ml, measured by a sufficiently sensitive LAL test. ISO 13959. 3rd edition 2014.

Determination of the bacteriological quality of the water and the dialysate shall include testing for microorganisms and endotoxins.

Maximum allowable levels of chemical contaminantsPurified water for haemodialysis shall not contain contaminant concentrations greater than those listed below (ISO 13959:2014 [see Appendix 5]):

| – Aluminium: Atomic absorption spectrometry | 0.01mg/l (10μg/l) |

| – Antimony: Atomic absorption spectrometry | 0.006mg/l |

| – Arsenic: Atomic absorption spectrometry | 0.005mg/l |

| – Barium: Atomic absorption spectrometry | 0.100mg/l |

| – Beryllium: Atomic absorption spectrometry | 0.0004mg/l |

| – Cadmium: Atomic absorption spectrometry | 0.001mg/l |

| – Calcium: Atomic absorption spectrometry | 2mg/l |

| – Chromium: Atomic absorption spectrometry | 0.0140mg/l |

| – Copper: Atomic absorption spectrometry | 0.100mg/l |

| – Fluoride: Ion chromatography | 0.200mg/l |

| – Lead: Atomic absorption spectrometry | 0.005mg/l |

| – Magnesium: Atomic absorption spectrometry | 4mg/l |

| – Mercury: Atomic absorption spectrometry | 0.0002mg/l |

| – Nitrate, as N Colorimetry | 2.0000mg/l |

| – Potassium: Flame photometry | 8mg/l |

| – Selenium: Atomic absorption spectrometry | 0.0900mg/l |

| – Silver: Atomic absorption spectrometry | 0.005mg/l |

| – Sodium: Flame photometry | 70mg/l |

| – Sulfate: Turbidimetry | 100mg/l |

| – Thallium: Atomic absorption spectrometry | 0.0020mg/l |

| – Total chlorine: Colorimetry | 0.100mg/l |

| – Zinc: Atomic absorption spectrometry | 0.100mg/l |

All these elements shall be tested at least once a year. Testing for aluminium shall be six-monthly.

For more details regarding the analysis technique, please consult Table 3 of ISO 13959:2014.

Purified water shall have maximum conductivity of 5μScm−1at 25°C (Appendix 5). In exceptional situations, below 20μScm−1at 25°C shall be allowed while the cause of the increase in conductivity is being identified. (Level of Evidence C, 2)

If, despite having a water treatment system with double osmosis in series or osmosis plus an electro-deionization system in series, conductivity of 5μScm−1 is not reached, provided it is below 20μScm−1 and all chemical contaminants listed in Section 4.1.2 are within specified limits, the existing level of conductivity shall be set as reference. In such cases, the cause of the increase in conductivity (e.g. carbon dioxide, pH, Na, etc.) shall be identified.

Once the reference level is set, whether below 5μScm−1 or in the case of the above exception, in the event of significant increases in conductivity by more than 30% of the reference level, testing of all chemical contaminants and feed water quality and identification of the cause of the increase in conductivity shall be required.

The conductivity of the treated water shall be monitored daily, with the value, plus the reasons for any significant changes, being recorded.

The conductivity meter shall be calibrated at least once a year and we emphasise the utility of comparing it with the TDS.

The recommended maximum concentration of aluminium in treated water is 0.005ppm (5μg/l). (Level of Evidence C, 2)

4.2Highly purified water for haemodialysisHighly purified (ultrapure) water should be used to produce ultrapure dialysate for all types of haemodialysis. (Level of Evidence C, 1)

4.2.1Microbiology4.1.2Maximum allowable levels for microbiological purityIn terms of bacteriological requirements, highly purified water used for diluting the dialysis concentrate shall contain fewer than 10CFU/100ml (0.1CFU/ml). ISO 13959. 3rd edition 2014.

Specifications (see Appendix A.3.1)In order to measure these quantities accurately, it is necessary to analyse a sample of highly purified water greater than 100ml by filtration.

Action levels for microbiological purityWe recommend that action be taken when bacterial growth in cultures is visible with the presence of more than 5 CFU/100ml of viable aerobic bacteria. To increase the accuracy of colony counts, the volumes processed should be greater than 100ml. Cultures shall be repeated with a greater volume of sample and duplicate samples; if contamination is confirmed, disinfection should be performed to prevent the formation of bacterial biofilm.

Maximum allowable levels of endotoxinsThe endotoxin content in highly purified water for haemodialysis shall not exceed 0.03EU/ml, measured by a sufficiently sensitive LAL test. ISO 13959. 3rd edition 2014.

4.2.2Maximum allowable levels of chemical contaminants in highly purified waterHighly purified water for haemodialysis shall not contain chemical contaminant concentrations greater than those specified for purified water for haemodialysis (Section 4.1.2andAppendix 5).

Highly-purified water shall have maximum conductivity of 5μScm−1at 25°C (Appendix 5). In exceptional situations, below 20μScm−1at 25°C shall be allowed while the cause of the increase in conductivity is being identified. (Level of Evidence C, 2)

If, despite having a water treatment system with double osmosis in series or osmosis plus an electro-deionization system in series, conductivity of 5μScm−1 is not reached, provided it is below 20μScm−1 and all chemical contaminants listed in Section 4.1.2 are within specified limits, the existing level of conductivity shall be set as reference. In such cases, the cause of the increase in conductivity (e.g. carbon dioxide, pH, Na, etc.) shall be identified.

Once the reference level is set, whether below 5μScm−1 or in the case of the above exception, in the event of significant increases in conductivity by more than 30% of the reference level, testing of all chemical contaminants and feed water quality and identification of the cause of the increase in conductivity shall be required.

The conductivity of the treated water shall be monitored daily, with the value, plus the reasons for any significant changes, being recorded.

The conductivity meter shall be calibrated at least once a year and we emphasise the utility of comparing it with the TDS.

The recommended maximum concentration of aluminium in treated water is 0.005ppm (5μg/l). (Level of Evidence C, 2)

4.3Design of a water treatment systemThere is no one water treatment system generic to all dialysis units since much depends on: chemical and bacteriological quality of the feed water to be treated, its origin and possible variations in the elements dissolved in it over time; architectural constraints; quantitative needs; qualitative needs; financial budget; and prospective changes, both in terms of the water treatments themselves and new dialysis techniques.

The basic components of a water treatment system for haemodialysis shall include a pre-treatment, where most of the undesirable elements are removed, and treatment with reverse osmosis and some other element that would achieve the level of purified water as part of its normal operation, generally a second stage of osmosis. (Level of Evidence C, 1)

Pre-treatment shall have at least one filter capable of retaining particles in suspension or sediment, water softener and charcoal filter (Appendix A.2.1) designed for the characteristics of the feed water supply, with duplicate equipment if levels of the element to be removed are considered high and could cause serious problems in the event of failure. (Level of Evidence C, 1)

It is essential to be aware of the potential problems at later stages as a result of poorly-designed pre-treatment; chlorine can damage the osmosis membranes or the presence of calcium can saturate them, or these elements can pass into the distribution network and so reach the patient.

The charcoal filter shall always be installed immediately pre-RO, as close as possible, as once the water is dechlorinated, there is a serious risk of contamination, particularly when passing through other filters where the speed slows down. (Level of Evidence C, 1)

When the feed water contains high levels of chloramines and other organic contaminants, or municipal, industrial or agricultural water contamination, the use of two activated charcoal filters in series is recommended.

Osmosis membranes shall be installed post pre-treatment, interposing a filter of at least 5μm, to avoid the possibility of small charcoal particles passing through, this being an essential element of treatment to obtain water that meets the quality requirements set out in the cited standards.

Installation of other elements post osmosis stage guarantees better water quality. Such elements may consist of: a second stage of osmosis, fed by the permeate from the first, with independent pumps between the two stages so that, in the event of failure of one, the other can continue to supply water; or an electro-deionization system. Resin deionization systems are not recommended due to the high risk of contamination (see Appendix A.2.1).

Both electro-deionization systems and UV lamps should always have ultrafilters installed which are capable of retaining up to the endotoxin concentration limit; electro-deionization systems have no filtering capacity and the bactericidal action of the UV lamps can add endotoxins to the water.

The working tank prior to the RO shall be as small as possible. The elements post first osmosis stage shall be installed in such a way as to allow different configurations, so they may be added to or complemented; a second stage of osmosis is recommended as the best option.

Elements which can be disinfected and/or descaled shall have the capacity to have accessories fitted to allow this function to be performed as quickly and reliably as possible: incorporated disinfectant metering pumps, programmed wash systems, built-in programmes in the equipment itself and sampling points.

4.4Water storage and distributionOnce treated, the water shall be distributed directly to points of use without storage tanks or drums, with the surplus being returned to the treatment entry point. The piping and plumbing shall be designed to prevent bacterial contamination and be easily disinfected. (Level of Evidence C, 1)

StorageTreated water shall not be stored as this makes it liable to contamination. Storing water creates difficulties for disinfection.

As there are no tanks of treated water, supply of feed water must be guaranteed, and the systems may therefore be as follows:

- –

Double water supply.

- –

Feed water tank, which shall have the characteristics described below and in Appendix 2 (A.2.1.1).

- –

Pre-treated water tank, with the same characteristics as the above point. In the case of the pre-treated water tank, some type of preservative or disinfectant treatment is required to guarantee that the water does not become contaminated.

If water tanks do exist, regardless of the volume, they shall be hermetically sealed, opaque, preferably stainless steel and have a conical base with the water outlet at the bottom and a 0.2μm antibacterial vent filter. The water inlet must be in shower form.

The volume of water required to complete a day's operation of the haemodialysis unit shall be guaranteed.

Distribution networkTreated water is highly inclined to acquire substances from the elements it comes into contact with, so the distribution network shall be made with materials that do not leach anything into the water, or are not suspected of being able to do so (copper, iron or aluminium pipes cannot be used), shall have no dead legs, using continuous piping with no joints or intersections, and be as short as possible. If stainless steel is used it must be pharmaceutical grade. The pipe that feeds the machine from the distribution network should be considered as an integral element of the distribution network. It has to circulate at a speed that minimises the risk of contamination and biofilm formation, >1m/s, so the section has to be precisely calculated. Unused water shall return to the water treatment system and go through it again.

Joins in the plastic materials form recesses and mean sudden changes in the linearity of the pipe that lead to reservoirs and disruption of the laminar flow; plastic materials which do not exhibit these drawbacks are now available on the market. Such connections are found in elbow joints when installed to change the direction of the pipe and in diversions to machines and valves. When opting for a particular type of material, consideration has to be given to how the connections are made, whether welded or using adhesives, due to the possibility of adhesives breaking down over time and leaching undesirable elements into the water. Polymer pipes and tubes are now available which do not have these drawbacks and resist heat without deforming. This type of material should be used for the distribution network (see Appendix 2). If the option is stainless steel, it has the advantages that thermal or chemical disinfection systems can be used and that it is resistant to accidental impacts and traction. The type of welding on stainless steel piping is crucial to prevent subsequent corroding of welded joints.

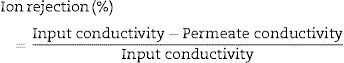

Dead legs must be completely avoided; outlets to machines shall be considered as dead legs and therefore shall also be avoided, with the emphasis on those where the pipes are translucent. The distribution network therefore has to go to the machine; one way to do this would be by installing a U-bend, where the distribution network goes to the machine and returns, then goes on to the next machine; this has the disadvantage that the pipe leading to the machine has the same section as the rest of the network.

The other way to do it is with secondary rings: a primary circuit distributes water throughout the unit and a secondary circuit carries the water to the machine; obviously, the dimensions of this secondary circuit are smaller than the primary; in the event of breakage or blockage, only the machine connected to it would be affected.

The above figures show the different configurations to ensure constant flow of water to the machine: U-bend installation on the left and secondary rings on the right.

Endotoxin retentive filterThe distribution loop for haemodialysis water shall be fitted with an endotoxin filter when any of the following three conditions exist: there is storage of treated water; double-pass osmosis is not available; post UV lamp, if the quality level to be achieved is of ultrapure water. The endotoxin filter shall preferentially be fitted at the beginning of the loop.

Thermal disinfection systemThermal disinfection systems are highly recommended and should at least be installed for the treated-water distribution loop. In conjunction with the secondary rings and the disinfection methods, combined with that of the haemodialysis machines, they are the most effective way of preventing the development of biofilm in the haemodialysis water distribution loop. Moreover, they avoid the risk of contamination of the dialysate by chemical disinfectants.

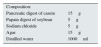

The following diagram shows a possible configuration for a water treatment system.

4.5Water treatment systems in special and mobile units and for home dialysisHaemodialysis water treatment systems in Special Units, such as high-dependency, ICU, resuscitation, etc. shall have the same characteristics as those described above and have the capacity to produce purified water for dialysis, as specified in this guideline, while being subject to the same controls and preventive measures as the other haemodialysis water treatment systems.

Water treatment systems for home dialysis and mobile dialysis units shall at the very least be fitted with an activated charcoal filter, reverse osmosis and a 0.2μ bacteria filter. The water quality shall be monitored monthly, as specified in Section 7 of this guideline, and the system shall undergo preventive measures as described in Section 8. Once it has been verified in an initial biochemical analysis that the substances referred to in Section 4.1.2 are at allowable concentrations, the conductivity of the osmosis permeate (or product) water shall be recorded and taken as reference. Sudden and significant changes in conductivity shall be investigated. After periods of inactivity, if the water treatment system is to be used again, the same methodology shall be applied.

Home haemodialysis machines shall come with their own endotoxin ultrafilter, which shall be replaced according to manufacturer's instructions.

5Concentrates for dialysisThe solute supply systems for the production of dialysate may be individual, for a single haemodialysis machine or central, for a group of machines.

The water used to produce concentrate for dialysis shall at the very least comply with the standards required for purified water specified inSections 4.1.1and4.1.2. (Level of Evidence C, 1)

Ideally, it should have the level of quality required for water for injection.

Currently, only bicarbonate shall be used as basic concentrate.

Its composition should be adjusted according to the clinical situation of each patient, as is done with other factors that influence the efficacy and safety of haemodialysis.

The concentration of solutes identified on the labelling shall be present to within a margin of ±5% or 0.1mEq/l, with the exception of sodium and chloride where the margin of variability shall be ±2.5%. These margins are expressed relative to the concentration in the dialysate after dilution of the concentrates. ISO 13958: 2009.

All the components shall be stated on the labelling along with their quantities and level of purity. The dilution to be used shall be stated as parts of concentrate per parts in the final solution (dialysate). The labelling shall state the expiry date, which guarantees its stability.

If the concentrates contain non-traditional components, the margin of tolerance for such components shall be ±5% of the nominal concentration of that component.

We recommend that manufacturers should provide chemical and microbiological quality certificates for the batches of concentrates supplied.

The containers, including caps and stoppers, shall be made of materials that do not interact with the concentrate, thereby contaminating it, and shall be airtight.

5.1Individual concentratesAcid concentrateAn acidic solution of concentrated salts which may contain dextrose. It is diluted with purified water and the bicarbonate concentrate to produce dialysate. In general, most patients can be dialysed with standardised ion concentrations in acid concentrate, although the type of concentrate should be individualised for each patient. (Level of Evidence B, 1)

Bicarbonate concentrateA concentrated solution of sodium bicarbonate which is diluted with purified water and the acid concentrate to produce dialysate. Some bicarbonate concentrates also contain sodium chloride. (Level of Evidence C, 1)

Current recommendations are that bicarbonate in powder form should be used for producing dialysate. (Level of Evidence C, 1)

Surplus bicarbonate from dialysis shall be discarded. (see Appendix A.2.2). (Level of Evidence C, 2)

Bicarbonate and citrate concentratesThe acid concentrate usually contains acetic acid as stabiliser for the mixture with bicarbonate. It is used at concentrations of 3–10mmol/l. Such concentrations cause transfer of acetate to the patient during HD, raising blood acetate concentrations. Exposure to acetate is increased in on-line haemodiafiltration techniques. The increase in blood acetate levels has been associated with a number of undesirable effects in the patient and there have been efforts for some considerable time now to find other acids to use as stabilising agents for dialysate. Citrate dialysate is a new alternative to using acetate as acidifying agent. Citrate is a calcium-chelating agent that is also used for its anticoagulant effect as it reduces calcium ion concentrations. A number of long-term beneficial effects have been described in relation to citrate, including reduced thrombogenicity, improvement in clearance, inflammation, nutrition and tolerance, and improved control of acid-base balance leading to less pre-dialysis acidosis. More scientific evidence is required to justify switching from acetate to citrate in all haemodialysis.Citrate concentrates suitable for different machines are currently available on the market, without acetate or with a mixture of the two stabilising agents.

Forms of presentationAcid concentrate comes in:

- •

Container

- •

Bag

- •

Dry cartridge of sodium chloride+bag of ions

- •

Bulk delivered concentrate (see Section 5.2)

Under this classification, we have presentations that facilitate individualisation of treatment, others that do not and those with which individualisation is impossible. The bulk system makes individualising treatment difficult or even impossible in terms of the concentration of solutes in the dialysate.

The dry cartridges of sodium chloride plus ion bag fully facilitate individualisation without increasing the storage space required; since they are single-use, they are also very safe.

The containers of concentrate allow individualisation, but an increased number of formulas have to be stored, meaning more space is required, and they can be less safe.

Bags allow individualisation, take up less space and are preferable in terms of safety since they are single-use and cannot be refilled.

Bicarbonate concentrate comes in dry cartridges or containers:

We recommend that containers of bicarbonate shall no longer be used, replacing them with bicarbonate powder cartridges. (Level of Evidence C, 2)

5.2Central concentrate systemsIndividual concentrate systems are preferable to central concentrate systems from the point of view of safety and individualisation, but they are more expensive and create greater problems in terms of storage and waste. The central production systems for bicarbonate concentrate are the most liable to microbiological contamination and are therefore not recommended. (Level of Evidence C, 1)

In situ central concentrate generator system shall be designed to include a source of purified water, easy draining and grounding for electrostatic discharge. They shall be made with materials that do not cause contamination to water, are non-corrosive and prevent the formation of mould and algae.

Tanks used to store the mixture shall be emptied and cleaned of debris and residue before using other concentrate baths in order to prevent cross-contamination between the different concentrate formulas. Use of additives in the acid is prohibited, as they can distort the composition of the dialysate; only potassium or calcium may be added and this shall always be indicated on the labelling, stating the final concentration.

Sodium bicarbonate tanks are not recommended but, if used, in addition to meeting the above characteristics, the walls and bottom shall be cleaned and disinfected. Sodium bicarbonate may be used in liquid or powder form. In both cases, but particularly with powder, the concentration shall be monitored prior to distribution; generally between 34mEq/l and 40.8mEq/l.

The other mode consists of bulk delivered concentrate. They come in large containers or cisterns and are then delivered directly to the dialysis machine. The installation shall allow sufficient space and adequate access for that purpose.

The distribution network for concentrates shall be colour-coded, with the outside of the pipes painted red for those delivering acid mixture and blue for sodium bicarbonate. We also recommend that the tanks should be translucent so that levels are always visible; level-indicator tubes should not be used, especially not in the case of bicarbonate, due to the risk of bacterial growth.

The acid concentrate distribution systems and, if applicable, the preparation tank, must have programmes for disinfection, descaling and cleaning of the installation, and this shall be done at regular intervals, at least annually, to guarantee optimal microbiological quality of the system. See Section 8.2.

5.3MicrobiologyThe maximum allowable levels for microbiological contamination shall be identical to the purity level for purified water at the end of valid shelf-life. Microbiological contamination levels for concentrates are the same as for purified water (seeSection 4.1). (Level of Evidence C, 2)

Once opened, containers of individual bicarbonate concentrate shall be handled with care to prevent further bacterial contamination. Previously-opened containers shall not be re-used; any fraction left over from a dialysis session shall be discarded. (Level of Evidence C, 2)

Concentrates which have undergone some type of sterilisation or disinfection procedure shall be preferred.

5.4Chemical contaminantsThe grade of purity of the elements used for preparation of the concentrates shall be high and comply with the corresponding standards. Purified water shall be used to prepare concentrates. (Level of Evidence C, 1)

The manufacturer should specify the requirements regarding chemical contaminant concentrations for purified water. In the United States, Chemical Grades are regulated by the USP/National Formulary. The salts used in the preparation of the concentrates can be a source of contamination and metal poisoning for the patient (see also ISO 13958: 2009).

6Dialysate qualityUltrapure dialysate qualityWe recommend that ultrapure dialysate shall be used for all types of haemodialysis, haemodiafiltration and haemofiltration.

6.1Maximum levels of microbiological contamination in dialysateMaximum allowable contamination in ultrapure dialysate is 0.1CFU/ml for bacteria and 0.03EU/ml for endotoxins. ISO 1163: 2009.

The testing method is the same as for highly purified water for haemodialysis.

To minimise inflammation in patients on haemodialysis, all dialysis units shall use ultrapure dialysate for all types of haemodialysis. The routine use of ultrapure dialysate requires the fitting of specific ultrafilters in the dialysate circuit. (Level of Evidence B, 1) The ultrafilters shall be used and replaced according to the manufacturer's instructions.There shall be a protocol for action when dialysate contamination is demonstrated in a haemodialysis machine. The action measures shall include withdrawal of the machine, replacement of the ET ultrafilter and general revision of the machine's operation. Full disinfection and descaling shall be carried out, including the point of connection to the loop, the tubing, the internal hydraulic circuit and the connectors.

6.2Maximum concentrations of chemical contaminantsThe specifications are the same as for purified and highly purified water (Sections 4.1.2 and 4.2respectively), except for the solutes used for the concentrates and the resulting conductivity. (Level of Evidence B, 1)

6.3Dialysate preparationA haemodialysis machine is a medical device designed to mix the concentrated electrolyte solutions or powder with the treated water to an electrolyte concentration, pH and temperature determined by medical prescription. The dialysate water shall be suitably degassed. The amount of electrolytes diluted in the water is monitored by dual systems, by measuring electrical conductivity and/or the pH of the final solution (pH meter). The temperature is monitored by thermometer. Before being delivered to the dialyser, the dialysate has to have passed through at least one ultrafilter. Hydraulic circuits in the machines, with no dead spaces, are preferred. A machine's entire hydraulic circuit has to have an automated and programmable disinfection system.

The conductivity and composition of the dialysate shall be exactly as prescribed by the doctor.

Regular use of ultrapure dialysate over the long-term helps prevent or delay a number of the complications associated with haemodialysis. (Level of evidence A, 1)

7Quality controlThe chemical and microbiological purity of water and HD fluid shall be monitored regularly and the results recorded. There shall be protocols in place with details of the procedures to be followed in the event that the performance limits or prescribed limits are exceeded. These protocols shall even contemplate the temporary closure of the dialysis unit when breach of the required safety limits reaches unacceptable levels. (Level of evidence C, 1)

7.1Technical monitoring of the process componentsDaily monitoring of key elements or parameters, which is easy and quick to oversee, helps ensure the proper operation of the various components of the water treatment system; it can also prevent an emerging problem in one component from developing and causing serious repercussions on some other part of the system, and ultimately affecting the quality of the treated water. Both feed water and treated water shall therefore be tested daily for the following: Free and total chlorine (chloramine) levels; hardness; and conductivity. At the same time, the pressures and flow rates in the different components of the water treatment and distribution equipment shall be monitored. (Level of Evidence C, 1)

Current mandatory requirements regarding the quality of water for haemodialysis mean that all the elements involved in producing this water need to be more strictly monitored. It is essential to keep an accurate record of all tests and procedures performed on the water treatment system and to follow the prescribed maintenance protocols for each element in the system. A protocol shall be drawn up in advance detailing the procedures to be followed in the event that faults are detected. The necessary procedures will depend on the particular water treatment system, the staff involved, characteristics of the unit, etc. so the protocol shall be written individually for each haemodialysis unit.

The technical and user manuals must be available for the different items of equipment. The staff responsible for monitoring shall receive sufficient training and information on all elements of the water treatment system and have the appropriate accreditation.

Routine testing can vary depending on the equipment and the quality of the water to be treated; in some cases it may be necessary to perform tests more frequently, especially in the validation or commissioning phase. In this phase, testing should be done daily, at least at the start of dialysis sessions and on completion of the last of the day, to check the effectiveness of the filter elements, both to verify the correct volume of the these elements and the programming of regeneration and/or backwash steps.

The frequency of monitoring of the water treatment system is based on two levels, for both technical and analytical monitoring: the first level, during the validation of a new treatment plant, refurbishment of an old facility or after a contamination requiring corrective action; the second level, during maintenance, day-to-day management of the treatment system, after the end of the validation period. The tests to be performed can be classified into three areas: technical; chemical; and microbiological.

The following table is intended as an aid to organising the tests to be performed. It should be used to complement the testing instructions provided by the equipment manufacturers; although, given the context in which their equipment is used, they can at times be a bit “relaxed” about the frequency.

| Element | Daily testing | Monthly testing and procedures | Comments |

|---|---|---|---|

| Flow rates and pressures (pressure gauges) | Check throughout the course of the treatment for any abnormal variations in pressure. | Certain automatic actions of the treatment system, essentially self-cleaning, cause variations in the normal pressures. | |

| Entry of feed water | Pressure | Measure chlorine – chloramines, hardness and conductivity. | Increase testing frequency if changes in conditions are suspected: drought, irrigation in the proximity, work on cisterns, etc. Any change can affect elements of the treatment system or the final quality and make some type of modification necessary. Compliance with Royal Decrees 140/2003 and 865/2003 |

| Prefiltration (sand, iron-retention filters, etc.) | Pressure difference between input/output and state of the programmer. | If filters are auto-washable, verify operation of the wash cycle. | The operation or condition of subsequent elements may indicate the proper functioning of the prefilter. Make changes to the filter element following the manufacturer's or installer's instructions. |

| Water softener | Test hardness at output and record, indicating the softener active at that time and the remaining volume for the next regeneration. State of the salt (brine) tank. | Check consumption of salt, the various stages of regeneration, condition and operation of the control elements: flow meters; programmer; etc. | Alterations in conductivity pre-osmosis and decreased reject and permeate flow rates may be indicative of faults in the water softeners. Do not prolong the life of the resins beyond that recommended by the manufacturer. There are specific devices for monitoring hardness on-line. |

| Charcoal filter (dechlorinator) | Measure free and total chlorine (chloramines) at the output of each charcoal filter at maximum consumption. Should be done once per shift if there are no treated water tanks. If there are treated water tanks, also measure post tanks. | Check operation of the wash cycle - expansion. Condition of automatic control elements. Test subsequent filter. | Replace charcoal at least once a year. If there are two charcoal filters in series or parallel, it shall be possible to perform measurements independently. The condition of the subsequent filter is indicative of the operation of the charcoal filters. |

| Microfiltration prior to reverse osmosis equipment | Pressure difference between inlet and outlet. | SDI test. Microbiological testing pre-RO and/or disinfection, from the dechlorinator outlet to the feed inlet to the RO equipment, if repeated contamination or malfunction of the RO is detected. Depending on the results, the frequency can be extended. | This element, from the dechlorinator outlet to the RO equipment, is susceptible to growth of microorganisms of various kinds in the absence of chlorine; this can have a major impact on the final microbiological quality of the water, hence the need for prevention and/or monitoring. |

| Reverse osmosis equipment | Conductivity at inlet and outlet or total dissolved solids (TDS). Pressures and flow rates. Ion rejection. Check programmer (alarm history, overview). | Check operation of automatic actions not visible in usual operation such as night operation, auto-rinsing of membranes, etc. and equipment control and protection elements. | Perform disinfection and descaling of the membrane according to manufacturer's specifications. Respect flow rates and pressures specified by manufacturer; in the event of unexpected variations, a detailed analysis (chemical, bacteriological, endotoxins, SDI) should be carried out of elements pre and post RO equipment. |

| Element | Daily testing | Monthly or other frequency of testing and procedures | Comments |

|---|---|---|---|

| Electro-deionization system | Conductivity or resistance, pH. | Verify operation alarm and measurement systems. | Increase in conductivity (or reduction in resistance) or change in the pH suggests saturation or malfunction of some element, resulting in high risk of contamination. The alarm should be adjusted to very low levels to allow the defect to be corrected (≈1 Mohms/cm=1μS) |

| Ultrafilters | Inlet and outlet pressure, input, outlet and rejection flow rates. | Exclusive microbiological and endotoxin analysis should be carried out at the feed inlet and outlet to check for effectiveness, regardless of the analyses performed in the rest of the treatment system. | High risk of loss of pressure due to clogging. Respect the maximum useful life stated by the manufacturer (time or clogging). Whenever replacing, carry out disinfection of the corresponding part of the hydraulic circuit. Rupture carries the risk of massive release of retained elements, e.g. endotoxins. |

| Ultraviolet (UV) lamp | Light intensity 16–30 milliwatt-s/cm2 | Change the lamp according to the manufacturer's technical specifications. | |

| Distribution network (including water intake haemodialysis machines) | Check pressure at the inlet and outlet of the distribution loop. Circulate water through dead legs if any. Measure chlorine/chloramines when there are treated-water tanks. | Monitor disinfectant rinses when used. | Set disinfection schedule based on the characteristics and length of the network, product water quality, type of disinfection (thermal, chemical). Every disinfection shall be recorded along with the reasons (protocol or contamination). The outlet to a non-working machine shall be considered a dead leg. |

| Tanks | If for treated water, measure chlorine/chloramine levels and hardness in distribution network. | Switch drive pumps (automatic systems). Check operation of levels and alarms. | If for treated water, disinfect with the distribution network. Change vent filter according to specifications. If for raw or pretreated water, chlorine/chloramine levels have to be monitored to prevent contamination. Check for presence of silt and general cleanliness. |

| Haemodialysis machines | Machines in reserve shall be disinfected at least once a week and rotated periodically. Strictly comply with the manufacturer's instructions for disinfection, maintenance and monitoring, especially those relating to ultrafilters inserted in the dialysate delivery to the dialyser. Check that the waste pipes from the machines do not have physical contact with the piping they drain into (Floating drain or contactless drain); clean these last one” regularly to avoid deposit of substances from dialysis. Each machine shall have a maintenance and incidents record. | Haemodialysis machines, in effect, act as dead legs and can alter water quality and therefore that of the dialysate and, in extreme, cases, affect the entire unit. In specific cases (e.g. repeated contamination), microbiological monitoring of the drains may be necessary; be aware that these points are easily contaminated from the external environment, and results must therefore be interpreted based on that premise. | |

Monitoring of the water system should be performed at different points of the dialysate production process, at different frequencies according to the circumstances:

Validation period of a new water treatment system following installation or a major refurbishment, or after having detected high levels of contamination which required corrective action. What exactly constitutes a major refurbishment or corrective action can be difficult to define; the following scenarios should be taken as a guide:

- –

Any change affecting designation as “Medical Device” of any of the equipment, according to Royal Decree 1591/2009.

- –

Changes in feed water quality resulting in installation or modification of any part of the pre-treatment and/or osmosis equipment.

- –

Repeated contaminations which, in addition to the appropriate disinfection, require modification of any part of the installation due to being identified as possible source of the problem.

The validation period for a water treatment system refurbishment can be compatible with the operation of the haemodialysis unit. After the refurbishment, a full disinfection shall be carried out and the proper operation of all the elements of the water treatment system and that the conductivity of the treated water is <5μS/cm−1 shall be verified. At the same time, the analytical tests specified in this section shall be performed.

- –

Maintenance period: Maintenance of a system in routine operation.

Microbiological monitoring of purified and highly purified water shall be done weekly for the first month after commissioning of the unit (validation phase). If any of the cultures or ET are positive, the necessary corrective measures shall be taken and the validation period extended for a further month. Subsequently, and during the maintenance phase, monitoring shall be carried out at least once a month. (Level of Evidence C, 2)

Testing for endotoxin levels shall be performed monthly in both the validation and maintenance periods. (Level of Evidence C, 2)

Each centre shall establish a written protocol setting the frequency, method and responsibilities for these tests. Operational units shall test the quality of the dialysis water at least monthly, using the culture methodology and sampling points specified in this guideline. For more details, see Appendix A.3.1.

Sampling points for microbiological cultures: In the validation period, samples shall be collected of the following: feed water; softened water; the water immediately pre-RO equipment; the treated water immediately post-RO; water from the end of the distribution loop and from at least 10% of the water intakes for the machines (HD stations); and the dialysate on entry into the dialyser in a minimum of 10% of the machines.

Microbiological testing of the water shall not be performed within the first 24hours following disinfection.

In the maintenance period, samples of the treated water shall be collected for cultures and ET from the first point and last point of the loop, post osmosis and at 10% of the connection points to the machines. After 12 months, samples shall have been taken from connection points to all the machines, including unused connection points. Samples of dialysis fluid shall be taken for cultures and ET pre-dialyser in 10% of the machines. After 12 months, all machines, including reserves, shall have been tested. (Level of Evidence C, 2)

In the maintenance period, it is not necessary to take samples of feed water or samples from intermediate points of pre-treatment, unless contamination is detected or alteration in the quality of the treated water suspected.

Sampling should be carried out post charcoal filter and pre reverse osmosis equipment, especially if there is no specific protocol for regular disinfection of this section.

For machines, the same criteria shall be followed as in the validation period, such that all machines shall undergo microbiological testing at least every 12 months.

In facilities with storage tanks for treated water, samples shall also be taken pre and post tank, generally coinciding with the outlet from the osmosis equipment and the beginning of the distribution loop respectively.

In the event of environmental microbiological contamination of the haemodialysis unit, additional samples may be taken of the drainage from the machines, but it is important to be aware that this section of piping is exposed to external contamination, because of its proximity to or direct contact with the drainage system.

In home haemodialysis with production of dialysate, microbiological monitoring should be done monthly, possibly alternating a water sample with a dialysate sample.

There are local regulations and guidelines which are stricter in terms of number of samples and testing frequency.

7.2.2ChemicalConductivity, corrected to 25°C, shall be measured continuously in the permeate from the osmosis. The reading shall be visible and connected to an alarm system to alert any changes.

Water hardness, free chlorine and total chlorine (chloramines) tests shall be performed daily. The sampling points are specified inSection 7.1. They should preferably be performed prior to the first haemodialysis session of the day.

Testing for all chemical contaminants specified inSection 5.2(maximum levels of chemical contaminants) shall be performed twice in the validation period and annually in the maintenance phase. Aluminium shall be monitored every six months.

The sample for the determination of chemical contaminants shall be obtained from one of the water connection points to the machines.

Water hardness shall be tested daily using a titration method or permanently with an alarmed instrument. Regeneration shall be adapted to the cycle of volume, salt activity, capacity of the resins and the water hardness; the programmer status shall be checked daily.

If the disinfection system for potable water uses chloramines, concentrations in the water shall be determined indirectly by measuring the free and total chlorine and calculating the difference.

There are local regulations and guidelines which are stricter in terms of number of samples and testing frequency.

8Methods for correction and prevention8.1Methods for correction and prevention for waterThe procedures for disinfection, descaling and detergent action are an integral part of the maintenance system for the water plant and distribution network. The frequency, type of disinfection and descaling (heat, chemical, mixed) and periodic changes in their components (filters, resins, membranes, ultraviolet lamps) shall be according to the manufacturers’ instructions and based on the results of the microbiological tests. (Level of Evidence C, 1)

The aim of maintenance of a dialysis-water treatment system and dialysis machines is to prevent contamination, not treat it. Methodology based on treating contamination is not acceptable. Prevention is based on scheduled disinfections, with frequency and type depending on the design of the water treatment system and the dialysis machines. Analytical tests are used to verify proper operation, not to indicate when disinfection is necessary. (Level of Evidence C, 1)

Automated disinfection systems should be used in the treated-water distribution circuit; they may operate by heat or chemicals, or be mixed, and should include an endotoxin filter. Automated systems make it easier and safer to maintain microbiological standards. Frequent automatic programming helps prevent contamination. We recommend programmable thermal disinfection of the distribution loop for maintenance of highly purified water production. (Level of Evidence C, 1)

It is important that the construction materials for the circuit do not contribute to chemical contamination of the water (aluminium, zinc, copper, etc.) and are compatible with the different disinfectants to be used in maintenance. The most suitable materials for a water distribution circuit are: stainless steel (at least SS316); acrylonitrile butadiene styrene; cross-linked polyethylene (PEX-A); polypropylene; polyvinyl fluoride and polyvinyl chloride and new materials such as PVDF (polyvinylidene fluoride). Whichever the case, they shall be labelled for sanitary use and CE marked. Materials resistant to high temperatures should always be used as preference.